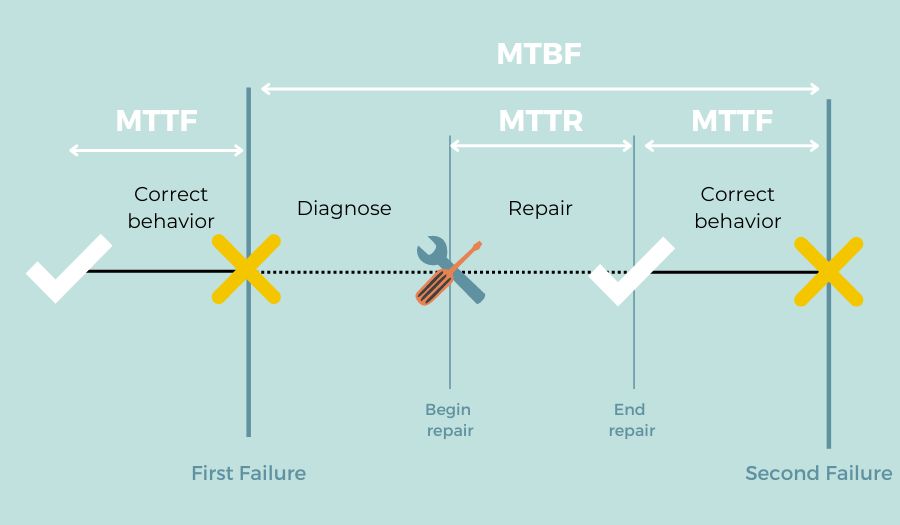

MTTR, MTBF, and MTTF are important reliability metrics used to measure the maintainability, reliability, and availability of repairable systems. Understanding the differences between these metrics is crucial for product designers, reliability engineers, and maintenance teams.

What is MTTR?

MTTR stands for Mean Time To Repair. It measures the average time required to repair a failed component or device. MTTR only considers the time spent on the repair process. It does not account for logistic delays such as waiting for spare parts. MTTR is calculated as:

MTTR = Total repair time / Number of repairs

MTTR is an important maintainability metric. A lower MTTR indicates that repairs can be completed quickly when a failure occurs. This improves availability and reduces downtime. MTTR depends on factors such as:

- Ease of diagnosis

- Accessibility of failed components

- Modularity of design

- Availability of spare parts

- Experience of maintenance crew

MTTR provides maintenance teams quantitative data to improve maintainability. It helps identify systems or components where repairs take longer. Steps can then be taken to simplify designs, improve diagnostics, or stock critical spares.

What is MTBF?

MTBF stands for Mean Time Between Failures. It is a reliability metric that provides the average time between repairable system or component failures. MTBF is calculated as:

MTBF = Total operating time / Number of failures

MTBF only considers the up-time between failures. The actual down-time during repairs is not included in the MTBF calculation. A higher MTBF indicates better reliability. An unreliable car that breaks down often would have a low MTBF. While an industrial machine designed for durability and reliable operation would have a high MTBF.

For repairable systems, MTBF is theoretically equal to the sum of MTTF (Mean Time To Failure) + MTTR (Mean Time To Repair). However, MTBF calculations often exclude logistics delays in the repair process. So MTBF is lower than MTTF+MTTR.

MTBF provides designers quantitative reliability data to improve new product development. If the MTBF does not meet the target reliability level, corrective actions can be taken like derating components, adding redundancy, or using higher quality parts.

What is MTTF?

MTTF stands for Mean Time To Failure. It is a reliability metric that defines the expected time between inherent failures of non-repairable components or systems. MTTF is calculated as:

MTTF = Total operating time / Number of failures

MTTF is used to quantify the reliability of non-repairable items like electrical components, batteries, or devices that are discarded upon failure rather than repaired. A higher MTTF indicates a more reliable product with longer life expectancy. MTTF helps set reliability goals during new product development. System and component MTTF values can be combined to estimate overall reliability.

For non-repairable systems, MTTF represents the mean lifetime. However, for repairable systems, MTTF only accounts for the mean up-time between failures. It does not consider the downtime during repairs. So MTTF is higher than MTBF which includes both up-time and downtime.

Key Differences Between MTTR, MTBF, and MTTF

Here is a summary of the key differences between these metrics:

| Metric | Definition | Used for |

|---|---|---|

| MTTR | Average time to repair failed system | Repairable systems |

| MTBF | Average time between failures | Repairable systems |

| MTTF | Average time to failure from beginning of life | Non-repairable systems |

- MTTR focuses only on repair time. MTBF and MTTF include operating time between failures.

- MTTR does not account for logistics delays like waiting for parts. MTBF may exclude logistics time.

- MTBF applies to repairable systems. MTTF is used for non-repairable components.

- MTTF represents total lifetime for non-repairable items. MTTF is longer than MTBF for repairable systems.

Uses of MTTR, MTBF, and MTTF

Here are some examples of how these metrics are used:

MTTR Uses

- Benchmark overall maintainability of equipment.

- Compare maintainability of different product designs or models.

- Set maintainability goals for new product development.

- Identify equipment or components needing maintenance improvements.

- Plan spare parts inventory based on expected repair times.

- Calculate availability of repairable systems.

MTBF Uses

- Benchmark reliability of products or systems.

- Set reliability goals for new designs.

- Compare reliability of different components, subsystems or vendors.

- Estimate rate of equipment failure occurrences.

- Calculate availability of repairable systems.

- Determine maintenance frequencies and schedules.

- Analyze failure data to improve designs.

MTTF Uses

- Estimate useful life of non-repairable components like batteries.

- Compare reliability of different electronic components.

- Set reliability goals for new products based on component MTTF.

- Determine warranty period for non-repairable products.

- Calculate failure rates of components.

Relationship Between MTTR, MTBF, and Availability

For repairable systems, the metrics MTTR and MTBF combine to quantify availability. Availability is the percentage of uptime that a system is operational and can perform its function. It is calculated as:

Availability = (MTBF / (MTBF + MTTR) ) x 100%

A higher MTBF indicates less frequent failures, while a lower MTTR means faster repairs. Both improve availability. Maximizing availability is crucial for many systems like servers, production equipment, or vehicles to minimize disruption and lost productivity.

As an example, consider a system with MTBF = 365 days and MTTR = 1 day. Its availability would be:

Availability = (365 / (365 + 1)) x 100% = 99.7%

Improving MTBF to 400 days, while reducing MTTR to 0.5 days would increase availability to:

Availability = (400 / (400 + 0.5)) x 100% = 99.9%

How to Calculate MTTR, MTBF, MTTF

MTTR, MTBF, MTTF can be calculated from failure and operating time data as follows:

Calculating MTTR

∑ Total repair time for n repairs / n

Example:

- System failed 3 times in past year

- Failure 1 – Repair time: 3 hours

- Failure 2 – Repair time: 2 hours

- Failure 3 – Repair time: 4 hours

MTTR = (3 + 2 + 4) / 3 = 3 hours

Calculating MTBF

∑ Total operating time / Number of failures

Example:

- Machine operates 8000 hours/year

- 3 failures occurred in past year

MTBF = 8000 hours / 3 failures = 2667 hours

Calculating MTTF

∑ Operating time until failure / Number of units tested

Example:

- Tested batch of 100 processors

- Total operating time until failures: 45,000 hours

- Number of processor failures: 10

MTTF = 45,000 / 10 = 4500 hours

Reliability and Maintainability

MTTR, MTBF, and MTTF provide quantitative data to measure reliability and maintainability. Reliability is the probability that a system will perform its purpose adequately over a specified time. It focuses on avoiding failures through robust designs. Maintainability measures how effectively a system can be repaired and restored to operation when a failure occurs. Maintainability is primarily influenced by the design factors below:

- Modularity – Systems designed in modules with replaceable parts enable faster fault diagnosis isolation and repair.

- Accessibility – Easy access to internal components aids testing, inspection and replacement of failed parts.

- Simplicity – Straightforward designs with minimum interdependencies between subsystems simplifies troubleshooting and repair.

- Standardization – Use of standard components and designs improves availability of spare parts.

- Diagnostics – Built-in sensors, indicators and test points help identify failed components rapidly.

While reliability aims to prevent failures through robust design, maintainability focuses on easy and quick restoration after a failure occurs. Reliability and maintainability are complementary disciplines that together determine system availability.

Importance of MTTR, MTBF, MTTF Data

MTTR, MTBF, and MTTF metrics provide invaluable data to drive design and maintenance improvements. Here are some key benefits:

- Quantify maintainability – Targets can be set for maximum acceptable MTTR as a maintainability benchmark.

- Identify poor reliability – Systems or components with low MTBF can be redesigned to improve reliability.

- Compare design alternatives – MTBF and MTTF data allows objective comparison of different architectures or vendors.

- Optimize testing – MTTF data allows qualification testing period to be set based on required reliability level.

- Improve availability – Using MTTR and MTBF data to maximize system availability by balancing reliability vs maintainability.

- Predict failures – MTBF helps estimate likely failure frequency and plan preventive maintenance accordingly.

- Warranty periods – MTTF data can help define warranty period for non-repairable products.

MTTR, MTBF, MTTF metrics turn subjective reliability and maintainability assessment into quantitative continuous improvement data. They allow design deficiencies causing frequent failures or time-consuming repairs to be systematically identified and addressed.

Conclusion

MTTR, MTBF and MTTF provide valuable metrics to measure maintainability, reliability and availability. While MTTR focuses on maintainability, MTBF and MTTF measure reliability. MTBF applies to repairable systems which are maintained by replacing modules. MTTF is used for non-repairable components with fixed lifetimes. Maintainability factors like modularity and accessibility are key to minimizing MTTR. Reliability is improved by robust designs that avoid failures leading to higher MTBF and MTTF. Analyzing failure and repair data identifies poor reliability or maintainability. This drives continuous improvement in availability, safety and total cost of ownership.