Wear leveling is a technique used in flash memory and solid-state drives (SSDs) to prolong the lifespan of the memory. The key purpose of wear leveling is to distribute writes as evenly as possible across all the physical blocks of memory to avoid premature failure of frequently written blocks.

What causes wear and tear in flash memory?

Flash memory has a limited lifespan and can only withstand a certain number of erase/write cycles before becoming unreliable. Typically, flash memory cells are guaranteed to withstand around 10,000-100,000 erase/write cycles before wearing out. However, the actual endurance varies based on factors like the quality of the flash memory and how it is used.

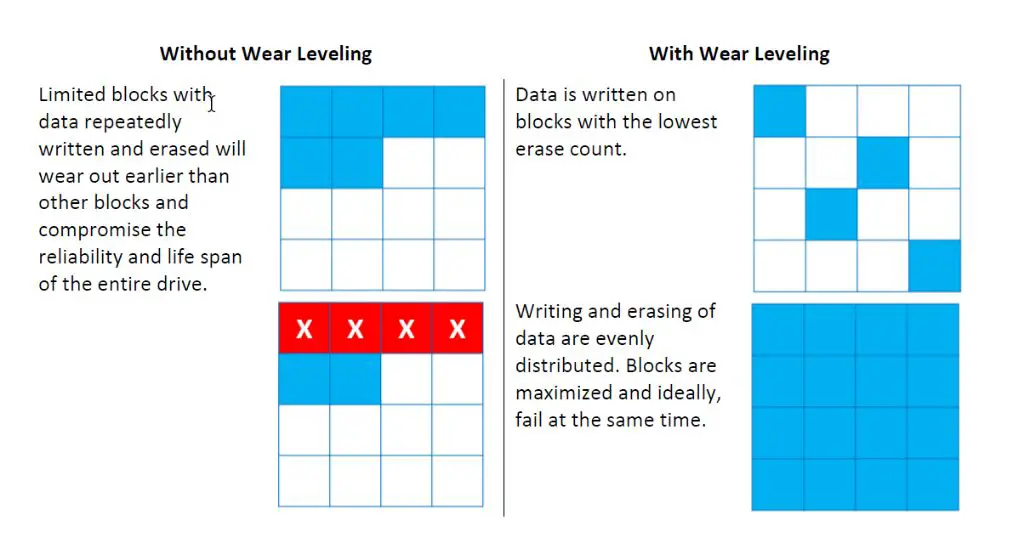

When a section of flash memory is repeatedly written and erased in a short period of time, it can wear out faster than other areas that are less frequently accessed. This uneven wear is problematic because once a few cells wear out, the entire block becomes unreliable.

How does wear leveling work?

Wear leveling aims to distribute writes evenly so no single block prematurely fails. It works by dynamically remapping logical block addresses to different physical blocks. When data is rewritten, instead of overwriting the original block, the data gets written to a different physical block and the mapping table is updated to link the logical block address to the new physical block.

This prevents excessive writes to any single block by essentially spreading out the writes across the physical memory space. The wear leveling algorithms keep track of erase counts for each block and attempt to direct writes to blocks with the lowest erase counts.

What are the different types of wear leveling algorithms?

There are several common wear leveling algorithms that are implemented in various ways:

- Dynamic wear leveling – Remaps blocks dynamically as data is written to distribute writes evenly. Typically requires more advanced logic and larger mapping tables.

- Static wear leveling – Swaps static data around at regular intervals to distribute wears. Simpler logic but can have higher write amplification.

- Global wear leveling – Keeps track of all blocks across the entire drive and swaps blocks between planes/chips as needed.

- Local wear leveling – Only swaps blocks within localized regions, like within a plane or erase block.

What are the key benefits of wear leveling?

Here are some of the major benefits provided by wear leveling:

- Extends the usable lifetime and endurance of flash memory and SSDs

- Prevents early failure of frequently programmed blocks

- Allows all physical memory to be utilized, rather than just a small fraction

- Improves overall performance consistency and reliability

- Reduces need for excess over-provisioning to account for wear

Without wear leveling, SSDs and flash drives would have much lower capacities and lifespans. Wear leveling allows the use of all available physical capacity regardless of wear by remapping logical blocks.

What are the limitations of wear leveling?

While wear leveling is effective, it does have some limitations:

- Introduces write amplification – rewrites cause additional writes.

- Can have performance overhead due to remapping logic.

- Requires larger mapping tables to track logical to physical mappings.

- Is not foolproof – uneven wear can still occur.

- Cannot recover blocks that have completely worn out.

Advanced wear leveling algorithms attempt to minimize these limitations by reducing amplification and optimizing performance. But there are inevitable trade-offs between efficiency, performance, and simplicity of implementation.

What are the main differences between wear leveling in HDDs vs SSDs?

Hard disk drives (HDDs) and solid state drives use very different wear leveling approaches due to their different underlying storage technologies.

In HDDs, wear leveling mainly involves tracking damaged sectors and remapping them to spare sectors set aside for replacements. This remaps relatively infrequent bad sectors.

In SSDs, wear leveling is much more complex and performance-critical. The algorithms must constantly remap large blocks of flash memory transparently to distribute erases. This occurs much more frequently than sector remapping in HDDs.

SSD wear leveling is also more preventative, spreading writes early before wear occurs. HDD wear leveling simply responds to relatively rare bad sectors as they arise.

Conclusion

Wear leveling is critical technology that allows NAND flash memory and SSDs to function reliably for thousands of erase cycles. Without wear leveling, flash cells would wear out very quickly and unevenly. By transparently remapping logical addresses to distribute writes, wear leveling significantly extends flash memory life to meet user needs.

While early flash devices had simple static wear leveling, modern SSD controllers implement advanced dynamic global wear leveling algorithms to optimize performance and flash longevity. However, there are still limitations as wear leveling introduces write amplification and cannot recover truly dead cells. Overall, wear leveling enables the widespread use of flash storage today by minimizing premature failures and maximizing usable device capacity over time.

Examples of Wear Leveling in Action

Here are a few examples that illustrate how wear leveling works in practice:

Updating a file

When a file is updated:

- The SSD controller receives the write request and identifies the logical block address being updated.

- Instead of overwriting the original physical block, the data is written to a new empty physical block with low wear.

- The mapping table is updated to link the logical block address to the new physical block.

- The original physical block is marked as invalid and ready for erasure.

This remaps the logical block to distribute writes across more physical blocks.

Static vs. dynamic wear leveling

With static wear leveling, physical blocks may be swapped around periodically, like weekly. For example:

| Logical Block Address | Physical Block Address |

| 0 | 10 |

| 1 | 20 |

| 2 | 30 |

After static wear leveling swaps blocks around:

| Logical Block Address | Physical Block Address |

| 0 | 30 |

| 1 | 10 |

| 2 | 20 |

With dynamic wear leveling, remapping happens on-the-fly as writes occur. For example, Logical Block 1 gets continually remapped as it’s updated:

| Write # | Logical Block Address | Physical Block Address |

| 1 | 1 | 105 |

| 2 | 1 | 203 |

| 3 | 1 | 418 |

| 4 | 1 | 2 |

This shows dynamic remapping occurring with each write to distribute wear.

Best Practices for Wear Leveling

To leverage wear leveling most effectively and maximize the lifespan of flash memory, following certain best practices is recommended:

- Use SSDs with controllers that support dynamic wear leveling algorithms.

- Enable the TRIM command if supported to notify SSD of invalid pages.

- Limit the use of static data that never changes to minimize amplification.

- Fill up drives as much as possible – wear leveling works best with high utilization.

- Use SSD monitoring tools to view wear levels across blocks.

- Set over-provisioning to recommended levels to provide space for wear leveling.

- Minimize excessive small random writes which are more amplified.

Following the manufacturer’s usage guidelines can also help optimize wear leveling effectiveness and drive lifespan.

Example Scenarios Demonstrating Wear Leveling Benefits

Here are two examples showing the benefits of wear leveling in realistic scenarios:

Database Server

A database server writes transaction logs repeatedly to a tablespace – without wear leveling, this high write frequency would cause early failure of the associated blocks.

With wear leveling, the tablespace logical blocks are transparently mapped to different physical blocks over time. This distributes the writes across all available blocks, avoiding premature failure of the high traffic tablespace blocks.

OS Drive

An OS drive has certain static binaries, libraries, and configuration files that rarely ever change. The OS also generates lots of logs, caches, and frequently updated user files.

Wear leveling ensures static files get remapped across blocks periodically so they don’t wear out specific blocks. The frequently rewritten blocks get dynamically remapped on each update to distribute wears.

Together this balances wears across the drive despite very different access patterns between static and dynamic data.

Wear Leveling in SSDs vs. USB Flash Drives

SSDs and USB flash drives both rely on wear leveling to extend lifespan, but with a few key differences:

- Algorithm complexity – SSDs use more advanced global dynamic wear leveling suited for continuous operation.

- Mapping table size – SSDs maintain much larger address mapping tables to track all logical to physical mappings.

- Over-provisioning – SSDs have more excess capacity (around 7-28%) for wear leveling compared to 2-5% in USB drives.

- TRIM support – SSDs actively reset pages flagged by the OS as unused to aid wear leveling.

- Write amplification – SSD wear leveling aims to minimize amplification, which is less of a concern for intermittent USB drive writes.

In general, wear leveling is implemented more comprehensively in SSDs since they operate continuously as primary storage with tight performance requirements.

Challenges of Scaling Wear Leveling to QLC NAND Flash

Newer quad-level cell (QLC) NAND flash poses challenges for wear leveling algorithms due to:

- Lower write endurance – QLC flash wears out faster.

- Larger block sizes – More data remapped on each write.

- Higher write latency – Wear leveling overhead more noticeable.

To scale wear leveling effectively to QLC NAND, controllers must:

- Use very low write amplification algorithms.

- Map at finer grain sizes to limit block sizes.

- Accurately measure cell wear in QLC blocks.

- Adaptively adjust algorithms based on real-time monitoring.

Efficient dynamic wear leveling optimized for QLC NAND characteristics is necessary to provide endurance and lifespan comparable to TLC SSDs.

Examples of SSDs and Controllers with Wear Leveling

Here are some examples of SSDs and flash controllers offering hardware and firmware-based wear leveling:

| SSD | Controller | Wear Leveling Type |

| Samsung 870 EVO | Samsung Pablo | Dynamic global wear leveling |

| WD Blue 3D NAND SATA SSD | WD in-house | Dynamic and static wear leveling |

| Kingston KC2500 | Phison E12 | Dynamic wear leveling with static data refresh |

| Seagate Nytro 5000 | Seagate custom | Dynamic wear leveling optimized for read-intensive workloads |

Most modern SSDs leverage advanced proprietary wear leveling algorithms implemented in hardware controllers combined with firmware optimizations.

Wear Leveling in USB Flash Drives

USB flash drives also utilize wear leveling, but with simpler algorithms suited for intermittent write patterns. Common examples include:

- SanDisk Cruzer – Uses a combination of dynamic and static wear leveling managed by the flash translation layer firmware.

- Samsung BAR Plus – Implements static wear leveling to remap static data. Dynamic mapping also occurs on detected frequently written blocks.

- Kingston DataTraveler – Combines dynamic wear leveling for day-to-day use with less frequent static wear leveling for optimal performance.

- PNY Pro Elite – Wear-leveling provides “wear evening” across cells to avoid write degradation on frequently updated logical addresses.

Overall, USB drives need less sophisticated algorithms focused only on improving flash longevity since storage performance is secondary in their use cases.

Conclusion

Wear leveling is a crucial technique used in modern flash storage to extend lifespan by evenly distributing writes across all physical memory blocks. Dynamic wear leveling algorithms remap logic blocks transparently to avoid over-wearing smaller regions of physical memory.

SSDs in particular rely on advanced global wear leveling schemes to optimize performance and endurance under continuous operation. Without wear leveling, flash-based storage would fail prematurely after as little as hundreds to thousands of writes. By leveraging wear leveling, today’s SSDs can reliably sustain tens of terabytes of writes over their usable lifespan.