Intel and Micron are two leading manufacturers of computer memory and storage technologies. In recent years, they have collaborated to develop new types of memory that could significantly advance computing performance. This article examines some of their key memory innovations and evaluates whether they represent true breakthroughs.

What is 3D XPoint memory?

One of the most hyped new memory technologies from Intel and Micron is 3D XPoint. Announced in 2015, 3D XPoint is a non-volatile memory that is faster than NAND flash memory but cheaper than DRAM. It aims to fill the gap between storage and memory in computing systems.

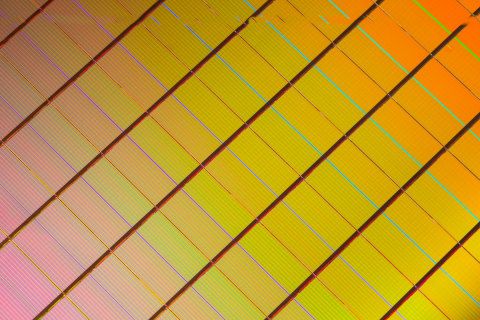

3D XPoint gets its name from its unique architecture. It stacks memory cells vertically in three dimensions to achieve greater density. The cells also change their electrical resistance to store data, unlike the charged cells used in flash memory.

Intel and Micron claim 3D XPoint is up to 1,000 times faster than NAND flash with 1,000 times greater endurance. This could enable systems to process data much faster by relying more on fast memory and less on slower long-term storage.

Is 3D XPoint really a breakthrough?

There are reasons to be skeptical about whether 3D XPoint fully lives up to Intel and Micron’s claims. Other manufacturers have struggled to replicate the technology, suggesting it may not be as groundbreaking as purported. Additionally, some analysts contend the real-world performance improvements over flash memory are more incremental than revolutionary.

However, 3D XPoint does appear to offer meaningful advantages over traditional memory solutions. The initial Optane SSDs using 3D XPoint memory provided two to four times the performance of the fastest NAND flash drives. And the second-generation Optane products were able to reach even higher speeds. 3D XPoint Dimms for servers also promise greater memory capacity without sacrificing speed.

While the cost and scalability of 3D XPoint remains uncertain, it does seem poised to make an impact. Intel and Micron may have overhyped its capabilities early on. But 3D XPoint now looks like an evolutionary rather than revolutionary advance, providing noticeable but incremental gains.

How does 3D XPoint work?

3D XPoint relies on a bulk material change of state for memory storage. Each memory cell contains a selector and memory element junction. Applying electrical pulses causes the material to switch between high and low resistance states, allowing it to store binary data.

The selector element helps isolate memory cells to improve performance and reliability. Meanwhile, stacking cells in three dimensions enables greater density versus a two-dimensional planar layout. Altogether, this architecture allows 3D XPoint to be faster than conventional flash with higher endurance.

Intel and Micron have not disclosed the exact composition of 3D XPoint material. However, it requires exotic materials and advanced fabrication techniques, including up to 1000 process steps. This contributes to the high cost of producing 3D XPoint currently. But as manufacturing scales, costs should moderate over time.

What is Intel and Micron’s newerFloating Gate cell 3D NAND technology?

In addition to 3D XPoint, Intel and Micron have jointly developed newer generations of 3D NAND flash memory. 3D NAND stacks flash memory cells vertically to achieve higher densities than planar NAND.

In 2017, Intel and Micron announced their first-generation 3D NAND technology called CMOS Under the Array (CUA). This moved peripheral logic circuits under the memory cell array to further increase density. However, it still used conventional floating gate technology to store data.

Their second-generation 3D NAND debuted in 2019 with a novel replacement for floating gates. Instead of storing charge, this new cell technology relies on changes in the cell’s resistance to indicate data values. This enables faster write speeds and higher endurance than previous 3D NAND.

How does floating gate 3D NAND work?

Conventional floating gate 3D NAND uses a similar architecture to planar NAND flash. Each cell contains a control gate and floating gate electrode made from polysilicon. Applying voltage causes electrons to tunnel through the oxide layer and get trapped on the floating gate, changing its threshold voltage to store data.

However, stacking cells vertically enables much greater density. The companies use a unique “punch and plug” process to create vertical NAND strings by etchingpillar holes, depositing layers, then filling in gaps with insulating material.

Compared to planar NAND, this 3D stacking achieves up to 256 Gb per die. The CUA technology further boosts density by movingsupport logic under the array. Yet the core floating gate technology remains unchanged.

How is the newer 3D NAND different?

Intel and Micron’s newer 3D NAND technology makes a more radical change, replacing the floating gate with a charge trap layer. Known as replacement gate (RG) 3D NAND, this design stores data in localized charge traps within thevertical channel.

With no floating gate needing high voltages to inject electrons, RG 3D NAND can operate at lower voltages. This enables faster write speeds, lower power draw, and greater reliability than previous generations. Endurance improves up to 50% and latency drops 40% over early versions of 3D NAND.

The companies are now on their fourth generation of 3D NAND using RG technology. With 144 layers, densities have reached over 1 Tb per die. Going forward, this technology could continue improving as layer counts increase further.

How does Intel and Micron’s 3D XPoint memory compare to other emerging memories?

Aside from 3D XPoint, other new memory technologies aiming to fill the gap between DRAM and storage include:

- Magnetoresistive RAM (MRAM)

- Ferroelectric RAM (FeRAM)

- Resistive RAM (ReRAM)

Here is how 3D XPoint compares to some of these other contenders:

MRAM

MRAM stores data using magnetic tunnel junctions. It can provide fast read/write performance and unlimited endurance. However, capacity remains limited and scaling is challenging. 3D XPoint has greater density potential today.

FeRAM

FeRAM uses ferroelectric layers that can be reversibly polarized to indicate data states. It provides faster writes than MRAM but lower memory density. 3D XPoint appears superior in density and performance.

ReRAM

ReRAM is resistive memory that alters conduction paths to store data. It may compete more directly with 3D XPoint in the future, but controllers and manufacturing are less mature currently. Intel and Micron have a head start with 3D XPoint commercialization.

In summary, no other new memory technologies yet match 3D XPoint’s blend of performance, endurance, and density. But the field remains competitive and other technologies may gain ground on 3D XPoint going forward.

What memory and storage products use 3D XPoint?

Intel and Micron have incorporated 3D XPoint into two main product families so far:

- Optane DC Persistent Memory Modules – High-capacity DIMM modules providing faster storage for servers.

- Optane SSDs – Low latency solid state drives for PCs and data centers.

Optane DC modules can work alongside DRAM to provide affordable large-capacity memory. Optane SSDs act as super fast storage or cache drives. Both aim to improve overall system performance.

Additionally, Intel offers Optane Memory modules for consumer PCs. These small SSDs can accelerate hard disk drives by caching frequently accessed data.

Overall adoption of Optane products has been fairly modest. But shipments are ramping up as performance benefits become clearer and new applications emerge.

What are the benefits of Optane DC Persistent Memory Modules?

Optane DC Persistent Memory Modules offer several advantages over conventional server DRAM:

- Higher capacity – Up to 512GB per module versus 128-256GB for DRAM DIMMs.

- Lower cost – 3-5x lower cost per GB compared to DRAM.

- Data persistence – Data remains after power cycles, unlike volatile DRAM.

- Fast access – Performance is much faster than SSDs or hard disk drives.

These modules aim to lower total cost of ownership for servers while improving performance for memory-intensive workloads. Their large capacity and persistence enables more data to stay in memory for faster processing.

Use cases

Some key applications for Optane DC Persistent Memory include:

- In-memory databases – Store entire datasets in memory cost-effectively.

- Data analytics – Speed up processing times for complex queries.

- Virtualization – Support more VMs with larger memory pools.

- High performance computing – Accelerate simulations, modelling, and more.

Both cloud infrastructure providers and enterprise data centers are deploying these modules to improve server efficiency and application performance.

What are the benefits of Optane SSDs?

Optane SSDs deliver faster access to data than NAND flash drives. Key advantages include:

- Lower latency – 10x faster random read, 3x faster random write over typical SSDs.

- Higher endurance – Up to 60 drive writes per day versus 1-10 for SSDs.

- Caching performance – Accelerate storage by caching hot data.

- Responsiveness – Greatly improve application load times and response.

These benefits stem from 3D XPoint’s faster speed relative to NAND. Optane SSDs excel at random access, benefiting many enterprise workloads.

Use cases

Some example uses for Optane SSDs are:

- Hot data caching – Speed up SAN storage access in data centers.

- Database acceleration – Faster transactions and query processing.

- Faster boot and loads – Consumer systems see improved response and load times for games and large files.

Optane SSDs can provide either primary storage or caching for higher latency hard disk and NAND drives. Their exceptional performance can directly speed up processing and improve user experiences.

What is Crystal Ridge? An upcoming new 3D XPoint product

A new platform called Crystal Ridge will expand use of 3D XPoint in data centers. With a PCIe 5.0 interface, Crystal Ridge will offer high memory capacity pooled from 3D XPoint modules.

Intel claims a single Crystal Ridge product will provide 4TB of memory capacity. This approaches DRAM capacity in a more affordable persistent memory solution. Memory pooling could also enable larger shared memory pools than possible with discrete Optane DC modules.

Expected to launch in 2023, Crystal Ridge aims to drive broader adoption of 3D XPoint. It will compete against next-generation DDR5 RDIMMs and LRDIMMs for high-memory servers. The ability to pool and scale 3D XPoint capacity to DRAM levels could give Crystal Ridge an edge.

What are the technical challenges and limitations of 3D XPoint?

While promising, Intel and Micron’s 3D XPoint technology faces some challenges:

- Expense – Manufacturing costs remain very high, limiting adoption.

- Complexity – The technology is difficult to produce with yield issues.

- Scalability – Stacking additional layers adds fabrication difficulties.

- Performance – Slow writes compared to DRAM, and slower than expected reads.

3D XPoint is clearly a major technical achievement. However, bringing this new memory into mass production has proven difficult. The companies continue working to refine the technology and improve yields.

How might 3D XPoint evolve in the future?

Intel and Micron see 3D XPoint as a long-term technology pathway. Future generations will likely focus on:

- Increasing layers – Adding more vertical layers to boost density and capacity.

- Expanded interfaces – Supporting more protocols like DDR5 beyond PCIe and DIMM.

- Process improvements – To lower costs and increase commercial viability.

- Innovative architectures – For example, pooling memory on Crystal Ridge.

3D XPoint has the potential to bridge the gap between storage and memory. But it will take time to scale manufacturing and reduce costs. Nonetheless, Intel and Micron appear committed to advancing this technology to create new computing possibilities.

Conclusion

Intel and Micron’s 3D XPoint memory certainly has disruptive potential. It can provide game-changing speed, endurance, and capacity for memory-driven workloads. Products like Optane SSDs and DC Persistent Memory Modules deliver tangible benefits today.

However, realizing 3D XPoint’s full promise remains an ongoing challenge. Manufacturing issues have hindered adoption, and costs are too high for mainstream applications currently. Rival memory technologies also may gain ground.

3D XPoint looks more evolutionary than revolutionary now. But Intel and Micron’s continued investment indicates they see a long-term future for this technology. If they can successfully scale 3D XPoint, it could transform how systems use memory and storage. But it will likely require years more of development to truly deliver on its lofty potential.