What is SSD endurance?

SSD endurance refers to how much data can be written to an SSD drive before it fails or starts to exhibit unacceptable performance degradation. It’s a measure of the drive’s lifespan and durability.

When data is written to an SSD, it causes wear on the NAND flash memory cells that store the data. Over time, this wear accumulates and the drive’s performance declines. SSD endurance ratings specify how much data can be written before this becomes a problem.

Why does writing data wear out SSDs?

SSDs use NAND flash memory to store data. NAND flash is organized into cells that can each store one or more bits of data. To write new data to a cell, the cell must first be erased.

The process of erasing and rewriting cells causes wear through a phenomenon called gate oxide degradation. The insulating layer in the cells, known as the gate oxide, wears down over time. As this oxide layer thins out, more charge can leak through and the cells become less reliable at maintaining the programmed state.

Excessive erasures can also lead to other issues like disturbance of neighboring cells and broken electrical connections in the flash silicon. All of this physical wear reduces the drive’s endurance over time.

How is endurance measured?

There are two main measurements used to quantify SSD endurance:

Terabytes Written (TBW)

This is the total amount of data that can be written to the drive before failure is likely. For example, a drive with a 300 TBW rating should be able to write 300 TB of data over its lifetime before wears out.

TBW is calculated based on testing drive samples under worst-case write conditions until a percentage fail. Vendors define the precise failure point, but 1% is common. The total TB written before reaching that failure rate becomes the endurance rating.

Drive Writes Per Day (DWPD)

This measures the maximum number of full drive writes that can be performed each day over the warranty period. A 1 DWPD rating means the SSD can handle a full rewrite of all data on it every day for the warranty period.

DWPD provides an endurance measurement normalized to the drive’s capacity and warranty length. It allows easier comparison between drives of different sizes and warranty durations.

What factors affect SSD endurance?

There are several factors that determine how much wear an SSD can handle before failure:

NAND flash type

SLC NAND Flash wears out slowest because it stores only one bit per cell. MLC stores two bits per cell and wears faster. TLC stores three bits per cell and has the lowest endurance. The more bits in each cell, the faster the erase/program cycles wear it out.

Wear leveling algorithms

The SSD controller uses these algorithms to spread writes across all cells evenly so wear is distributed. Better wear leveling means more even wear and higher endurance.

Over-provisioning

This refers to extra NAND flash capacity that is unseen by the user. The over-provisioned space allows more efficient wear leveling and improves endurance.

DRAM cache size

A larger DRAM cache buffers more writes so fewer writes actually hit the NAND flash. This reduces wear and improves endurance.

Operating temperatures

Higher temperatures accelerate the breakdown of the NAND flash cells, decreasing endurance. Proper cooling improves endurance.

Write amplification

Due to the nature of SSDs, the actual number of cell erasures is multiplied higher than the number of writes sent by the host. This write amplification factor directly reduces endurance.

How is TBW calculated by manufacturers?

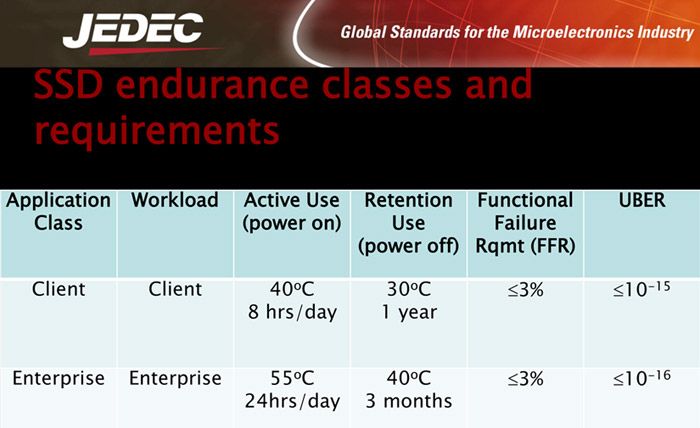

SSD vendors use standardized test procedures outlined by the JEDEC industry standards organization to measure terabytes written. The basic process is:

1. Fill the entire SSD with sequential data writes at maximum capacity to simulate consumer usage patterns.

2. Iterate overwrites continuously with more sequential writes until the drive fails for a percentage of samples.

3. The total TB written before the failure point becomes the TBW rating.

Vendors may customize test parameters like temperature, write patterns, and define failure as a certain bit error rate. However, the testing methodology remains similar across vendors.

Is the TBW rating accurate?

TBW ratings give a rough estimate of SSD lifespan but real-world endurance can vary significantly. Some factors impacting accuracy:

– Test conditions may not match real usage. writes are sequential during testing versus random in reality.

– Only small sample of drives are tested. Manufacturing variances mean endurance varies across production units.

– Warranty periods often exceed testing periods. The testing may be accelerated to predict longer warranty periods.

– Endurance varies based on usage. Light usage extends lifespan while heavy writes shorten it.

So TBW ratings are best treated as a general guideline of expected endurance, not an absolute guarantee. Real-world endurance depends heavily on individual usage patterns.

Does TBW guarantee the drive will last that long?

No, the TBW rating does not guarantee the SSD will last for the rated number of terabytes written. It is simply a manufacturer’s prediction of expected endurance under ideal conditions. Real-world endurance can vary substantially based on these factors:

– Usage patterns – heavy writes wear out the drive faster while light usage extends endurance.

– Operating temperatures – higher temps accelerate wear.

– File types – certain highly compressed files like videos cause more write amplification and wear.

– Luck – manufacturing variances mean some units will simply fail sooner than others.

So an SSD is not guaranteed to last for its full TBW rating. That rating is just a general guidance based on accelerated testing. In the real world, many SSDs continue working well past their rated endurance.

Is DWPD or TBW more important?

DWPD and TBW provide complementary endurance ratings that are both useful for gauging SSD lifespan. DWPD allows easier comparisons between drives of different capacities and warranties. TBW gives the absolute endurance number for a specific model.

In general, DWPD is more meaningful for comparing relative endurance between SSDs. TBW ratings depend heavily on capacity – a higher capacity model inherently has a higher TBW. DWPD normalizes for capacity so provides a better apples-to-apples endurance comparison between models.

But for estimating the expected lifespan of a specific SSD model, the TBW rating is most important. It tells you the total terabytes of writes projected before failure for that specific capacity. Combined with your actual usage levels, it helps predict how long that model should reasonably last.

How does file compression affect endurance?

Highly compressed files like videos, JPEGs, and ZIP files actually reduce SSD endurance compared to uncompressed data. This counterintuitive effect occurs due to write amplification.

Write amplification is the ratio between the logical writes sent by the host and the actual NAND flash writes done by the SSD. Compressed data causes more write amplification for two reasons:

1. The files are smaller, so more need to be written to fill up capacity. This increases the total write commands.

2. Random writes are replaced by sequential writes. Sequential writes invalidate more existing data in flash pages, increasing erase cycles.

One test found video files caused 2.8x more write amplification versus text files. Since endurance is inversely related to write amplification, compressed media files substantially reduce SSD lifespan compared to uncompressed data.

How does SSD capacity affect endurance?

Larger capacity SSDs typically have higher endurance ratings for two reasons:

1. The TBW rating depends on total drive capacity. For example, a 500GB drive with 1 DWPD will have 500GB x 1 writes per day = 500TBW. A 1TB drive with 1 DWPD gets 1000TBW.

2. Higher density NAND flash chips are used in larger capacity drives. The finer manufacturing geometry wears out slower.

However, when normalized using the DWPD metric, endurance differences by capacity diminish because DWPD already accounts for capacity. Overall, larger SSDs last longer thanks to the higher TBW, but may not have inherently superior endurance per gigabyte written.

Why does SLC have the highest endurance?

SLC flash provides the highest endurance among NAND types because it stores just one bit per cell. This makes the cells more robust and resistant to breakdown through erase/program cycles for several reasons:

– Only two voltage states per cell instead of 4 or 8. Less potential for errors.

– Larger voltage gap between the two states. More tolerance against charge leakage.

– No need for tricky multi-level cell programming algorithms. Less stress on the silicon.

– SLC cells can typically handle 100,000 erase cycles versus 3,000-10,000 for MLC and TLC.

The downside is SLC is more expensive and less dense than MLC/TLC. But for applications requiring the highest endurance, SLC remains the gold standard.

How does drive usage affect endurance?

SSD endurance highly depends on the workload and usage of the drive. Light, normal consumer workloads allow SSDs to vastly outlast their rated endurance. But heavy workloads can wear out drives much faster than rated.

For example, a user who only reads data and rarely writes will see almost no wear. The drive should functionally last forever. But heavy write workloads like video editing, data analytics, or database applications will quickly accumulate writes and approach the rated endurance limit.

Also, client workloads with intermittent idle periods allow the SSD to recover through background garbage collection. Steady writes without idle periods cause heavier wear. So the same TBW rating can lead to widely different real-world endurance under different usage.

How does temperature affect endurance?

Higher temperatures accelerate the breakdown of NAND flash memory, decreasing SSD endurance. There are two key reasons:

1. Elevated temperatures speed up charge leakage through the thin tunnel oxide layers in NAND flash cells. This leads to faster breakdown of the insulation and more errors.

2. High temperatures cause electrons to gain enough energy to get stuck in the floating gate. These trapped electrons change the voltage thresholds and cause read errors.

Testing by Micron found operating a 3D NAND SSD at 95°C instead of 35°C reduced its endurance by 60-75% depending on the workload. SSD lifetime improves significantly by minimizing temperature through cooling techniques.

Can endurance be improved through firmware updates?

Yes, SSD manufacturers can extend endurance through firmware updates that optimize the flash translation layer (FTL). Two common optimizations include:

1. Improved wear leveling algorithms that more evenly distribute writes across all cells. This prevents “hot spots” of excessive wear.

2. Early retirement of worn-out blocks identified by diagnostics. This avoids placing data in unreliable blocks prone to failure.

For example, Samsung’s Magician software provides periodic firmware updates for its SSDs to implement advancements in wear leveling and error correction. These firmware updates help improve endurance and extend the usable lifespan of the drives.

How does DRAM size affect endurance?

Larger DRAM buffers improve SSD endurance by absorbing a greater number of writes. The DRAM cache stores frequently accessed “hot” data and write updates so that fewer writes have to hit the NAND flash.

This write absorbing effect reduces the total erase cycles on the flash memory. Intel testing found that doubling a SATA SSD’s cache from 256MB to 512MB reduced the write amplification factor from 14 to 11. This 25% reduction in write amplification directly improves endurance.

More DRAM also allows the controller to implement more sophisticated garbage collection routines further minimizing erasures. Overall, larger DRAM buffers are a key reason higher-end SSDs have better endurance ratings.

How is endurance affected by capacity utilization?

Lightly filled SSDs have longer endurance because empty blocks provide flexibility for wear leveling. Heavily filled drives force the controller to continuously reuse blocks, concentrating wear.

Intel research found endurance dropped by 2-3x on a heavily versus lightly filled SSD. The full drive forced blocks to be overwritten 50 times more than the empty drive before failure.

This shows that utilizing only a portion of an SSD’s full capacity preserves blocks for wear leveling rotations and extends endurance. However, performance may drop on lightly filled drives.

Can you estimate endurance based on usage?

Yes, a simple calculation allows estimating approximate SSD endurance based on your capacity and write usage:

Endurance (TBW) = SSD Capacity * DWPD * Warranty

For example, a 250GB SSD with 0.5 DWPD rating and 5 year warranty would have:

250GB SSD Capacity

* 0.5 DWPD

* 5 years

* 365 days per year

= 45625 TBW

So for this 250GB drive, writing 100GB per day would wear it out in about 456 TB or 4.5 years. This methodology allows reasonably estimating if endurance matches your usage needs.

How does over-provisioning improve endurance?

Over-provisioning refers to extra NAND flash capacity hidden from users or the OS. This reserved space allows the SSD controller to optimize writes and wear leveling, improving endurance.

The key benefits of over-provisioning include:

– Absorbing write bursts so user data writes are more even and predictable. This avoids concentrated wear.

– Providing spare capacity to relocate data during garbage collection without stalling user requests.

– Allowing fuller garbage collection by providing scratch space to consolidate data from partially filled blocks.

– Reducing write amplification since less data relocation is needed during garbage collection.

More over-provisioning means less user capacity but better endurance. Lightly filled SSDs also gain over-provisioning type benefits.

Conclusion

SSD endurance is a complex metric that depends on usage patterns, NAND characteristics, controller algorithms, capacities, temperatures, and more. But TBW ratings based on JEDEC standard testing provide a baseline for comparison. Real-world endurance varies and often exceeds this rating with normal consumer use. Understanding what factors impact endurance allows selecting the optimal SSD for a particular workload.