SSD endurance refers to how much data can be written to an SSD before it fails. It is measured in terabytes written (TBW). TBW ratings are essential for assessing SSD lifespan and reliability.

NAND flash memory has a limited number of program/erase cycles it can handle before it wears out. Each write operation consumes some of the endurance budget. Once the drive exceeds the rated TBW, wear-related errors start appearing and performance degrades until complete failure.

Higher endurance allows SSDs to withstand heavy write workloads for longer periods. This makes endurance critical for write-intensive enterprise applications. But it also matters for consumer SSDs, allowing them to last through their warranty period and beyond.

TBW ratings provide an estimate of the total data writes before failure. However, the way data is written impacts wear. The TBW spec is based on specific test conditions that may not reflect real-world usage. Nonetheless, it gives a standardized basis for comparing endurance between different SSDs.

How SSD Endurance Works

SSD endurance refers to the total amount of data that can be written to an SSD before the drive wears out. This is determined by how SSDs write data at the NAND flash cell level.

SSDs store data in NAND flash memory cells made up of floating gate transistors. To write data, a high voltage is applied to inject electrons through the tunnel oxide layer into the floating gate, changing the threshold voltage and programming a 0 or 1. Erasing resets the cell by removing electrons.

Each time a cell is programmed and erased, charge can get trapped in the insulating oxide. This builds up over time, making it harder to reliably read/write data. The cell wears out after about 10,000-100,000 write cycles typically.

To extend lifespan, SSDs use wear leveling to distribute writes across all cells evenly. But eventually cells wear out, leading to irrecoverable read errors once a certain number of writes are exceeded. This defines the drive’s endurance specification.

SSD controllers also use extra spare capacity and other reliability techniques like error correction to maintain performance as cells begin wearing out. But there is a finite endurance limit before too many cells are worn.

Measuring Endurance with TBW

TBW stands for “terabytes written” and it is a measure of how much data can be written to an SSD before it wears out. SSDs have a finite lifespan and can only withstand a certain number of write/erase cycles before individual memory cells start to fail. TBW ratings provide an estimate of the total amount of data that can be written to an SSD over its lifetime.

TBW is used as a measure of endurance because it directly correlates to the number of writes an SSD can handle. Each time data is written and erased on an SSD, it puts wear on the NAND flash memory cells. The higher the TBW rating, the more writes it can handle before failure. For example, an SSD with a 600TBW rating should be able to write 600TB of data before wearing out.

Manufacturers derive the TBW rating by testing SSDs under maximum write conditions in a controlled environment. The total terabytes written before a percentage of memory cells become unreliable is used to estimate lifespan. TBW provides an easy way for consumers to compare endurance between different SSD models.

TBW Ratings for Consumer SSDs

TBW ratings can vary significantly between consumer SSDs depending on the form factor and interface. Here are some typical TBW ratings:

SATA SSDs

2.5-inch SATA SSDs usually have lower TBW ratings around 150-600. For example, the Crucial MX500 1TB has a TBW rating of 360 (Source). The lower cost per GB of SATA SSDs means less overprovisioning and lower endurance ratings.

NVMe SSDs

M.2 NVMe SSDs have higher TBW ratings from 500-1800 for consumer models. The Samsung 970 EVO Plus 1TB is rated for 600 TBW (Source). The higher performance of NVMe allows for more overprovisioning cells and increased endurance.

M.2 SATA SSDs

M.2 SATA SSDs have similar TBW ratings to 2.5-inch SATA SSDs around 150-600. The WD Blue 3D NAND 1TB M.2 SATA SSD is rated for 400 TBW (Source). The interface and form factor do not affect SATA SSD endurance.

In general, NVMe SSDs have 2-4x higher endurance ratings than similarly sized SATA SSDs. But M.2 form factors do not automatically mean higher endurance. Look at the interface and controller to determine TBW ratings.

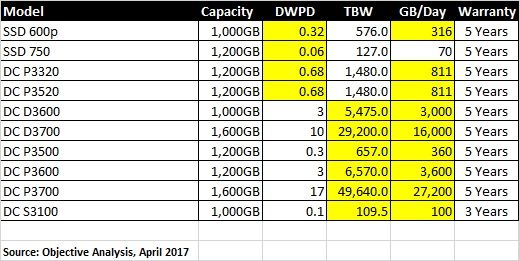

TBW Ratings for Enterprise SSDs

Enterprise SSDs are designed for more intensive workloads than consumer drives, and as a result have much higher endurance ratings. While consumer SSDs often have TBW ratings in the 150-600 range, enterprise drives can easily go into the petabytes.

For example, the Intel DC P4610 SSD aimed at data centers has a TBW rating of 16.2 petabytes, over 25,000 times higher than a typical consumer drive. Other enterprise SSDs from Samsung, Micron and Sandisk also boast TBW ratings in the 1-10+ petabyte range1.

The higher endurance allows enterprise drives to withstand the constant writing that occurs in servers and other enterprise applications. It comes from overprovisioning extra NAND capacity that can replace worn-out cells.

While the massive TBW ratings seem impossibly high, enterprise workloads can in fact fully utilize this endurance over several years of 24/7 operation. Still, most enterprise SSD warranties only cover 5 years, so the full TBW may not be realized within the warranty period.

Estimating Your SSD’s Lifespan

You can estimate the lifespan of your SSD based on its TBW (terabytes written) rating. The TBW rating specifies how much data can be written to the drive before it is likely to fail. This is usually provided by the manufacturer.

To estimate lifespan, you need to know your average daily write workload. Let’s say you have a 500GB SSD with a 300 TBW rating. If you write 10GB per day on average, you can calculate:

300 TBW / 10 GB per day = 30,000 days of writes

So the estimated lifespan would be around 30,000 / 365 = 82 years.

However, heavy workloads can wear out an SSD faster. If the daily write workload was higher at 50GB, the estimated lifespan would be closer to 16 years.

Overprovisioning your SSD can extend its lifespan by allowing more empty blocks for wear leveling. An overprovisioned 500GB SSD may have 550GB or more of flash memory chips. This provides extra space to spread writes over more cells.[1]

In the end, TBW ratings are just estimates. Actual lifespan depends on use case and write patterns. But TBW provides a starting point for estimating SSD endurance.

Factors That Impact Endurance

There are several key factors that can impact an SSD’s endurance and lifespan:

- Drive usage patterns – Frequent writes and erases will wear down an SSD faster than mostly read operations. Drives used for OS/apps tend to have much lower endurance than those used for data storage.

- Overprovisioning – Having extra spare area allows for better wear leveling and increases endurance. Consumer drives often have very little overprovisioning.

- Wear leveling algorithms – The controller firmware evenly spreads writes across all cells to avoid wearing out one area faster. More advanced algorithms improve endurance.

- Temperature – Higher temperatures degrade components faster. Enterprise SSDs designed for data centers have higher operating temperature ratings.

- Write amplification – The amount of actual NAND writes is multiplied versus the host writes. Lower write amplification improves endurance.

- NAND process – Smaller lithography NAND can withstand less erase cycles before wearing out. However, 3D NAND has much higher endurance.

Understanding these factors can give deeper insight into published endurance ratings and how different workloads impact SSD lifespan. Carefully considering usage patterns and matching the right SSD to the application is important for maximizing endurance.

Sources:

[SuperSSD] (https://www.superssd.com/en/kb/understanding-ssd-endurance/)

[Phison] (https://www.electronicdesign.com/technologies/embedded/article/21267454/phison-electronics-flash-memory-ssd-endurance-and-reliability-four-influential-factors)

Improving SSD Endurance

There are several ways to extend the lifespan of an SSD and improve its endurance. One of the most effective methods is overprovisioning, which involves leaving a portion of the SSD’s storage capacity unallocated. This allows the drive to spread out writes more evenly across all the flash memory cells, reducing wear and tear. Consumer SSDs typically come with 7-28% overprovisioning from the factory, but you can increase this yourself through disk management tools. Leaving 20-30% of the drive’s capacity unallocated is recommended for improved endurance.

You can also limit the number of writes to the drive by enabling TRIM, avoiding unnecessary writes, and enabling write caching. TRIM clears out deleted data blocks so they can be rewritten, while write caching bundles multiple small writes into larger chunks. Disabling indexing, search indexing, and defragmentation on the SSD can further reduce unnecessary writes. Following the manufacturer’s guidelines for workload limits and ambient operating temperatures will also help maximize SSD lifespan.

Finally, upgrading to an enterprise-grade SSD with higher quality NAND flash memory and more advanced wear-leveling algorithms will substantially improve endurance compared to a consumer drive. However, enterprise SSDs come at a higher cost. For most consumer workloads, moderate overprovisioning and limiting unnecessary writes provides sufficient endurance improvements.

SSD Failure Rate Statistics

Field data provides helpful insight into real-world SSD failure rates and lifespan. Backblaze publishes drive stats reports based on the thousands of SSDs operating in their data centers. Their 2023 mid-year review analyzed failure rates for over 3,100 SSDs from major brands like Samsung, Micron, and Kioxia.

The annualized failure rate for most SSDs was under 1%, with some models closer to 2%. This is still significantly better than hard disk drives. For example, the Crucial MX500 had a 0.21% AFR while the Samsung 860 EVO was 0.29%. These failure rates translate to an estimated lifespan of around 10 years for typical consumer SSDs.

Newer models with 3D NAND flash memory tended to have slightly lower failure rates. Enterprise-class SSDs designed for heavy workloads also fared well, like the Samsung PM983 with a 0.45% AFR. Overall, field data confirms modern SSDs offer excellent reliability under typical usage.

The Future of SSD Endurance

SSD technology continues to rapidly evolve, with manufacturers making constant improvements to lifespan and reliability. One of the most significant innovations in recent years has been the transition to 3D NAND flash memory. As described in an article on StoragePartsDirect, “3D NAND stacking allows for greater densities at lower costs while improving endurance” (Source). By stacking flash memory cells vertically, 3D NAND enables higher capacities and better performance in a smaller footprint.

According to industry projections, 3D NAND will dominate the consumer SSD market in the coming years. The increased endurance of 3D NAND compared to planar NAND enables drive manufacturers to offer longer warranties. For example, Samsung’s 870 EVO SSD with 3D NAND provides a 600 TBW rating and 5-year warranty, a significant improvement over previous generations. As 3D NAND production matures, density will continue to scale, further improving lifespan and reliability.

Beyond 3D NAND, other emerging technologies like QLC and PLC aim to pack even more bits per cell, though potentially at the cost of endurance. Advanced controllers using machine learning help optimize performance and compensate for any reduction in endurance. Overall, the rapid pace of SSD evolution ensures capacities will continue growing while endurance steadily improves in future generations.