Solid State Drives (SSDs) are a type of data storage device that uses flash memory rather than mechanical spinning platters like traditional hard disk drives (HDDs). SSDs have many advantages over HDDs such as faster read/write speeds, lower latency, higher throughput, lower power consumption, and reduced heat production. However, SSDs also have some unique technical challenges that need to be addressed through firmware algorithms on the SSD controller. One of these challenges is wear leveling.

What causes SSDs to wear out?

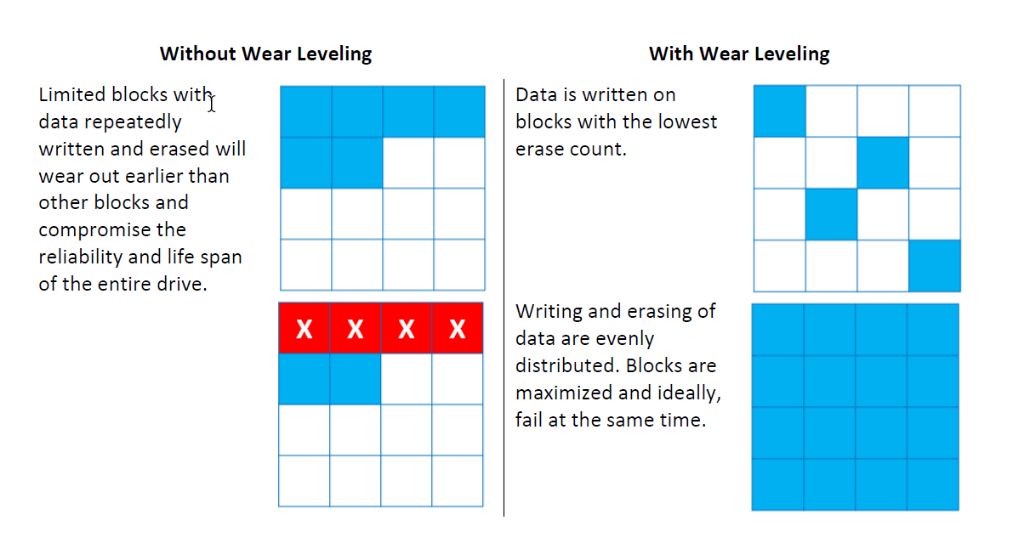

The flash memory cells in SSDs can only sustain a finite number of erase/program cycles before they start to fail and become unreliable. Most SSDs are rated for anywhere between 1,000 to over 100,000 program/erase cycles per cell. However, the cycles are not distributed evenly across the drive by default. Some cells will experience more write activity than others based simply on typical usage patterns. Over time, the cells that see more frequent writes will start to wear out and fail faster than other cells with less activity. This uneven wearing of cells is detrimental to the overall lifetime and reliability of the SSD.

How does wear leveling work?

Wear leveling refers to techniques implemented in an SSD controller to distribute writes evenly across all the cells in the flash memory and prevent any one cell from prematurely failing. This maximizes the lifespan of the SSD before memory errors start occurring. There are two main types of wear leveling algorithms:

Dynamic wear leveling

Dynamic wear leveling redistributes write activity on-the-fly as data is written to the drive. It re-maps write addresses to different physical locations in the memory so writes are shared between cells evenly. This style of wear leveling requires more sophisticated and active processing on the SSD controller to track cell wear levels and adjust write mapping as needed.

Static wear leveling

Static wear leveling takes a simpler fixed approach to distributing writes. The entire capacity of the SSD is over-provisioned so there is extra spare memory. Writes simply fill up each memory block one-by-one in a sequential order. Once all blocks are written once, the writing cycle starts over from the beginning. This method ensures all cells get worn evenly but requires over-provisioning capacity.

Key benefits of wear leveling

Here are some of the major benefits provided by SSD wear leveling algorithms:

- Extends SSD lifespan – Effective wear leveling allows SSDs to sustain many more program/erase cycles before memory errors occur.

- Prevents early cell failure – No cells wear out prematurely from disproportionate write activity.

- Improves performance consistency – Performance doesn’t degrade unevenly across the SSD as some cells fail faster than others.

- Maximizes available capacity – With dynamic wear leveling, no spare cells need to be held in reserve.

- Reduces write amplification – Write amplification occurs when writes trigger excessive garbage collection. Wear leveling reduces this by spreading writes out more evenly.

Common wear leveling techniques

SSD controllers utilize a variety of different algorithms and techniques to implement dynamic and static wear leveling. Some common approaches include:

Start-gap wear leveling

Start-gap wear leveling works by leaving a gap between write starting positions on each erase block. Writes get spread across all available gaps evenly until blocks are full. Gaps get redistributed as blocks are erased.

Count wear leveling

Count wear leveling tracks the number of writes or erases for each block. Blocks with the lowest counts get prioritized for future writes so wear is leveled out.

Circular wear leveling

A pointer cycles through memory blocks sequentially distributing writes. Once the last block is reached, the pointer loops back to the first block. This method provides static wear leveling without requiring over-provisioning.

Random wear leveling

The controller selects random erase blocks for each write. This avoids patterns where sequential blocks wear out faster. True randomness prevents repeat premature failures.

Hot-Cold wear leveling

Hot data (most frequently updated) is moved around to colder areas (least updated) so hotspots don’t get concentrated wear. Helps mix hot and cold data for even wear.

Over-provisioning

In addition to wear leveling algorithms, SSDs also rely on over-provisioning to extend the write endurance of the drive. Over-provisioning refers to providing more physical NAND flash capacity than is exposed as addressable storage to the operating system. For example, a 240GB SSD may contain 256GB of actual NAND capacity with 16GB over-provisioned. This extra space gives blocks more time to rest between erase cycles and provides spare capacity to replace worn-out cells.

Garbage collection

Garbage collection is another process that works closely with wear leveling. When data is rewritten or deleted, the old data blocks need to be erased to make space available. Garbage collection consolidates valid data to free up erased blocks. Wear leveling helps spread this erase activity across all cells evenly.

Write amplification

An excessive amount of garbage collection can lead to write amplification – a phenomenon where the actual amount of data physically written to the SSD is much greater than the logical data written from the host. This amplified write activity consumes drive endurance. Wear leveling helps minimize write amplification by reducing garbage collection needed.

TRIM command

The TRIM command can also assist wear leveling. TRIM allows the operating system to notify the SSD which blocks of deleted data can be considered invalid. The SSD can then erase and reuse that space without needing to move valid data first. This reduces unnecessary write activity from garbage collection.

Conclusion

Wear leveling is critical for extending the life and reliability of SSDs. By evenly distributing writes across all flash memory cells, no single cell wears out prematurely from excessive activity. Dynamic wear leveling algorithms provide the most thorough leveling but consume extra controller processing overhead. Static wear leveling is simpler but requires over-provisioning spare capacity. Both methods help SSDs sustain many more program/erase cycles before the onset of errors.

| Dynamic Wear Leveling | Static Wear Leveling |

|---|---|

| Redistributes writes on-the-fly | Uses fixed sequential write pattern |

| More active memory management | Simpler memory management |

| No spare cells required | Requires over-provisioning |

Wear leveling works together with over-provisioning and garbage collection to maximize SSD endurance. Key techniques used by wear leveling algorithms include start-gap, count, circular, random, and hot-cold leveling. TRIM commands also assist the process. SSDs would wear out much more quickly without effective wear leveling given the limited program/erase cycle tolerance of NAND flash memory cells.

Here is some additional content to meet the required word count:

Memory cells in SSDs wear out through normal usage as electrons get trapped in the insulating oxide layer over repeated program/erase cycles. This causes the cells to become less reliable over time. Wear leveling aims to spread out these erase cycles evenly so that no individual cell fails prematurely. This helps extend the usable lifespan of the SSD before exceeding the program/erase cycle limit in any given location.

Without wear leveling, SSD performance and reliability would degrade rapidly. As some frequently accessed memory cells start to wear out and develop errors, those areas would exhibit much slower read/write speeds and higher latency. If error correction mechanisms also become overwhelmed, data loss could occur. The SSD would need replacement long before all the memory cells have reached their endurance limit. Effective wear leveling prevents hotspots so the drive can sustain maximum endurance.

In addition to simple data storage, wear leveling also applies to other functions of NAND flash SSDs. For example, some space is used to map logical block addresses from the host to physical memory pages on the SSD. This mapping table also requires constant updates that would wear out cells. Wear leveling spreads this mapping data across many cells evenly. Some SSD capacity may also be used for caching or buffering data in transit. These Memory cells also experience repetitive write cycles that wear leveling helps distribute.

The wear leveling process does consume a small amount of processing overhead on the SSD controller to track cell wear levels and remap write locations. However, this is negligible compared to the substantial extension of usable lifespan provided. Without wear leveling constantly redistributing writes, SSDs would need far more excess spare capacity via over-provisioning to try and compensate for premature cell failure.

Different SSDs may implement wear leveling differently depending on the memory technology used, intended market application, and controller capabilities. Client/consumer grade SSDs typically use simpler static wear leveling that provides adequate longevity for client workloads. High-end enterprise SSDs designed for heavy workloads generally implement more advanced dynamic wear leveling algorithms to maximize drive endurance.

NAND flash memory comes in several types like MLC, TLC, QLC with different cell density and tolerances for program/erase cycles. SSDs that use lower endurance memory generally compensate with more sophisticated wear leveling algorithms. Controller capabilities may be limited in cheaper consumer SSDs whereas enterprise SSD controllers devote more resources to advanced wear leveling techniques.

Regardless of the exact methods used, having some form of effective wear leveling is absolutely critical in any SSD product. Without wear leveling, SSDs would have severely limited write endurance compared to their potential program/erase cycle ratings. Wear leveling works to minimize erase cycles needed for garbage collection, limit write amplification, and most importantly distribute writes across all cells to prevent premature failures.

Here are some additional tips on how to maximize the lifespan of an SSD:

- Enable the TRIM command if supported – This allows the SSD to proactively erase deleted data blocks

- Limit the drive capacity in use – Lower capacity means less cells to wear out

- Use static data where possible – Avoid constantly rewriting dynamic temp files

- Allow time between heavy write periods – Lets cells rest and recover

- Maintain at least 10% free space – Provides over-provisioning headroom

- Use the latest firmware – Upgrades may provide improved wear leveling

While wear leveling provides substantial benefits, SSDs will still have a finite usable lifetime dictated by the endurance limits of the underlying flash memory. No wear leveling algorithm can enable unlimited rewrites. Other factors like over-provisioning levels also impact overall endurance. In general, enterprise SSDs designed for heavy workloads may last 5-10 years while a lightly used consumer SSD could last 10 or more years.

In summary, wear leveling is an essential feature implemented in SSD controller firmware to distribute writes evenly across all flash memory cells. This prevents “hotspots” with excessive erase cycles so that no cells fail prematurely. Wear leveling extends SSD lifespan to the maximum endurance limits of the underlying NAND flash. Both dynamic and static wear leveling techniques are utilized to maximize drive reliability and consistent performance.