Wear leveling is a technique used in solid-state drives (SSDs) to prolong the lifespan of the drive. The process aims to distribute writes and erases evenly across all the cells in the SSD so that no single cell wears out prematurely.

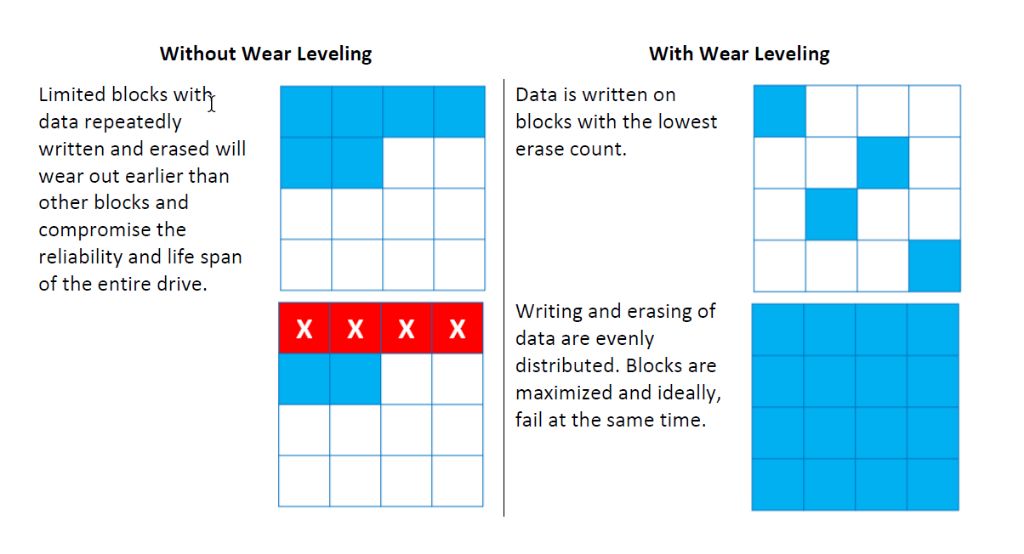

Without wear leveling, an SSD would overwrite some cells much more frequently than others. Since flash memory cells in SSDs can endure only a limited number of erase cycles before they become unreliable, this uneven use would cause some cells to wear out much faster than others. Once a cell fails, the SSD would lose capacity and its ability to store and retrieve data reliably.

Wear leveling aims to avoid this by arranging data so writes are distributed uniformly across all the cells in the SSD. This prevents localized wear and ensures all cells wear at approximately the same rate, maximizing the lifespan of the drive.

How SSDs Work

SSDs or solid state drives use flash memory to store data, unlike traditional hard disk drives that use spinning platters. The most common type of flash memory used in SSDs is NAND flash memory. NAND flash memory is made up of cells that can store charges to represent data. It is non-volatile memory, meaning data is retained even when power is removed.

NAND flash memory has certain limitations. One is that cells can only withstand a finite number of program/erase cycles before they wear out and can no longer reliably store data. This is why SSDs have a limited lifespan and endurance rating, often measured in terabytes written (TBW). The TBW rating refers to how much data can be written to the drive before performance may degrade or cells start to fail.

To extend the lifespan of SSDs, wear leveling techniques are used to distribute writes evenly across all the cells. This prevents some cells from wearing out prematurely compared to others. Wear leveling helps prolong the endurance of an SSD.

Why Wear Leveling is Needed

All SSDs suffer from uneven wearing of internal memory blocks over time. This is due to the fundamental way that SSDs function – by trapping electrons in transistors or cells to represent data as either a 1 or a 0. Each time a memory block is accessed or written to, a tiny amount of wear occurs [1]. If certain blocks are accessed more frequently than others, they will wear out faster. Eventually this can lead to failure of overworked blocks, prematurely shortening the lifespan of the drive.

Wear leveling techniques aim to distribute writes evenly across all blocks in an SSD. By preventing concentrated, excessive writing to any single block, wear leveling prolongs the usable life of SSDs significantly. Manufacturers claim this can increase lifespan by a factor of 10 or more compared to drives without wear leveling [2]. Effective wear leveling is thus crucial for enabling affordable consumer SSDs with reasonable lifespans.

Types of Wear Leveling

There are several different types of wear leveling techniques used in SSDs:

Dynamic Wear Leveling

Dynamic wear leveling keeps track of the number of program/erase cycles on each block and attempts to distribute writes evenly across the drive over time (TechTarget). When data is rewritten, it is moved to a new block with fewer erase cycles. This helps distribute the wear and maximize the life of the SSD.

Static Wear Leveling

Static wear leveling also redistributes data over time like dynamic wear leveling, but has the additional goal of keeping static data in place and not constantly moving it around the drive (MakeUseOf). This prevents unnecessary writes for data that doesn’t change often.

Global vs. Local Wear Leveling

Global wear leveling looks at the entire SSD and moves data between any blocks on the drive. Local wear leveling only migrates data within the same erase block or proximity group (Wikipedia). Most SSDs use a combination of global and local wear leveling techniques.

Dynamic Wear Leveling

Dynamic wear leveling, also known as dynamic logical block addressing (LBA), moves data around at runtime in order to distribute writes evenly across the flash memory and prevent any single block from wearing out prematurely. This type of wear leveling uses a mapping table or algorithm to redirect write requests from the host to different physical locations in the flash memory.[1] The controller keeps track of erase counts for each block and attempts to direct writes to blocks with the lowest counts.

The main advantage of dynamic wear leveling is that it allows “on-the-fly” adjustments during normal operation, ensuring the most even wear across the drive over time. However, the continuous data shuffling requires more sophisticated and computationally intensive controller algorithms. There can also be a performance penalty associated with the constant remapping.[2]

Overall, dynamic wear leveling provides effective wear distribution but involves more overhead than static techniques.

Static Wear Leveling

Static wear leveling works by keeping track of used and unused blocks in the SSD and moving data from frequently written blocks to lesser-used areas during idle time, even if that data has not been updated [1]. This helps distribute writes more evenly across the drive to prevent premature wear and failure of frequently accessed cells.

The main advantage of static wear leveling is that it is more effective at extending the lifespan of the SSD compared to dynamic wear leveling alone. By proactively moving static data around, it helps ensure all cells get utilized evenly over time [2]. However, a drawback is that it only balances wear within a single NAND flash die, so there can still be differences in wear between chips.

Other Wear Leveling Techniques

In addition to dynamic and static wear leveling, there are some other wear leveling techniques used in SSDs:

Start-gap wear leveling: This technique leaves gaps between writing cycles to ensure writes are distributed evenly. It involves starting each new write at a different logical block address compared to the previous write. This helps spread out the wear over more cells.[1]

Random wear leveling: As the name suggests, this technique writes data randomly across the SSD to prevent concentrated wear on any one block. The SSD controller maps logical block addresses to varying physical locations.[2]

Gentle wear leveling: This method writes data gently to less-worn blocks first before utilizing other cells. The goal is to even out the wear gently over time rather than prematurely stressing lightly used blocks. It results in more gradual, balanced wear.[1]

These techniques help SSD controllers distribute writes in ways to maximize the lifespan of the NAND flash memory cells.

[1] https://www.makeuseof.com/what-is-ssd-wear-leveling/

[2] https://www.atpinc.com/blog/how-SSD-wear-leveling-works

Implementations

Wear leveling is typically implemented in the firmware of SSD controllers to evenly distribute writes across all flash blocks. The most common implementations are in the SSD controller firmware by manufacturers like Samsung, Intel, Crucial, etc. The controller handles all the underlying NAND management so wear leveling is transparent to the host operating system [Wear-Leveling Techniques in NAND Flash Devices](https://www.micron.com/-/media/client/global/documents/products/technical-note/nand-flash/tn2942_nand_wear_leveling.pdf).

Some operating systems like Linux also have filesystem-level wear leveling to provide redundancy. However, the OS can only see high-level block writes so it is less efficient than controller-level implementations. SSD controllers have full visibility into the NAND to distribute writes evenly across all pages and blocks [AN98521 – Wear Leveling](https://www.infineon.com/dgdl/Infineon-AN98521_Wear_Leveling-ApplicationNotes-v06_00-EN.pdf?fileId=8ac78c8c7cdc391c017d07429b0b65b0).

Dual-level wear leveling combining the controller and OS can provide robust protection against write amplification. But controller-based wear leveling is sufficient for most consumer SSDs and is transparent to the end user.

Impact on Performance

Wear leveling can impact SSD performance in terms of throughput and latency. The extra operations required for wear leveling can reduce throughput.[1] For example, static wear leveling requires more write amplification compared to dynamic wear leveling, resulting in lower write throughput.[2]

Wear leveling can also increase latency. The extra remapping and block erasures increase the time required for read/write operations.[2] However, newer wear leveling algorithms try to minimize the impact on latency. For example, dynamic wear leveling only remaps blocks during idle time to avoid impacting active operations.[3]

There is an inherent tradeoff between maximizing SSD lifespan through wear leveling and optimizing for performance. More advanced wear leveling algorithms aim to balance these competing objectives. The goal is to extend SSD lifespan as much as possible through even wear distribution while keeping any performance impacts manageable.[1]

Conclusion

In summary, wear leveling is an essential technique used in SSDs to extend their lifespan by distributing writes evenly across all flash blocks. It helps prevent any one block from wearing out prematurely. The two main types of wear leveling are dynamic wear leveling which works in real-time, and static wear leveling which is applied periodically. While wear leveling can slightly reduce performance, it is a necessary tradeoff for the huge endurance benefits.

Looking ahead, wear leveling will continue playing a crucial role as SSDs evolve. Emerging 3D NAND and newer flash technologies will bring their own endurance challenges that require intelligent wear leveling schemes. However, there are also new developments like HAMR that promise to increase flash memory endurance drastically, potentially reducing the need for wear leveling. But for now and the foreseeable future, wear leveling remains an integral part of delivering consistent and long-lasting solid state storage.